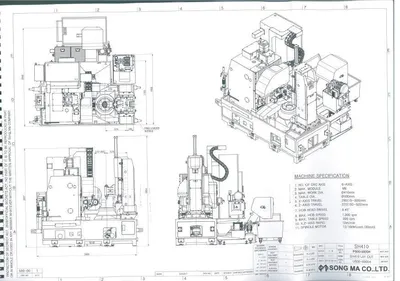

Presenting the Model SH410 Gear Hobbing Machine from SMG of South Korea! Featuring a clean-sheet design first produced in 2019, SMG has managed to produce hundreds of copies of a very rigid, compact hobber that has world-class features and benefits especially when compared to the competition. Featuring DRY or WET operation for starters, these machines are modular in their construction meaning modifications are possible in the field as production demands change. Torque motor tables, geared hob heads and conversational programming along with a standard hob pre-setting device make these machines worth a look.

Competitive with regard to price and range of accessories these machines are available with a variety of formats including manual & auto-load, Fanuc or Siemens controls and a large array of available automation. At work the world over, these hobbers are in high-production and job shop settings working around the clock.

This machine will be built to order with (Optional) extended X & Z Axis Travels as detailed herein. This machine requires 6 months to produce and 1 month to arrive in the United States.

SMG SH410 (EXTENDED) SPECIFICATIONS:

MACHINE CAPACITY: METRIC INCH

Max. Workpiece Diameter with ring loader: Φ410 mm 16.141"

Max. Workpiece Diameter manual machine: Φ415 mm 16.338"

Max. Workpiece Length: 885 mm 34.85"

Max. Module: M8 3.2DP

See "Working Ranges" (Below) for Additional Capacity Data.

WORK TABLE:

Max. Table Speed: 200 rpm

Table Drive Power 7 kW 9.4 Hp

Table Drive Torque 600 Nm 442 lb ft.

Table Outside Diameter: Φ330 mm 12.992" Φ330 mm 12.9"

Table Bore Diameter: Φ120 mm 4.724"

HOB HEAD:

Max. Hob Diameter/Length: 130/230 mm 5.1"/9.0"

Max. Hob Speed: 1000 rpm (Optional 1500, 2000 rpm)

Max. Hob Shift(Y-axis) Travel: 210 mm 8.267"

Hob Swivel Angle: ±45º

Hob Arbor Taper: BT #40

Hob Spindle Output: 15kW 20 Hp

Hob Head Torque: 900 Nm 663 lb ft.

Hob Arbor: Φ32mm Diameter Standard - Can Be Customized, Specify with Order.

(8, 10, 13, 16, 19.05, 22, 22.2225, 25.4, 27, 31.75, 32, 38.1 & 40mm)

WORKING RANGES:

X-Axis:

X-axis Travel (Extended)(Radial): 320(15~335) mm 12.59"(0.59"~13.19")

Z-Axis:

Z-axis Travel (Extended)(Axial): 600(150~750) mm 23.6"(5.9"~29.5")

TAILSTOCK:

Tail stock Center Travel: 400(305~705) mm 15.7"(12"~27.7")

Tailstock Pressure Max: 16,000 Nm 11,800 ft/lb.

*The attachment position of the tailstock housing can be moved up/down @ 240mm additionally, facilitating longer shafts.

FEED RATES:

X-Axis (Cutting): 0.1 ~ 500 mm/min 0.004 ~ 19.68"

X-Axis Rapid(Radial): 12 m/min 472 ipm

Z-Axis (Cutting): 0.1 ~ 500 mm/min 0.004 ~ 19.68"

Z-Axis Rapid(Axial): 12 m/min 472 ipm

Y-Axis (Cutting): 0.1 ~ 500 mm/min 0.004 ~ 19.68"

Y-Axis Rapid (Tangential): 5 m/min 472 ipm

_______________________________________________________________________________

MISCELLANEOUS SPECIFICATIONS:

Number of Axes: 6 (X = Column Travel - Radial)

(Y = Hob Shift)

(Z = Hob Head - Axial)

(A = Hob Head Swivel)

(B = Hob Rotation)

(C = Table Rotation)

CNC Control Systems: Fanuc 0iM-F - OR - Siemens 840D SL - is an Option

All SMG Machines incorporate UPS Systems - Automatic Power Failure Retract Systems.

Floor Space(L x W x H): 2776x3329x2990 mm 109"x 131"x 117"

Machine Weight: 11,000 kg 24,250lbs

Total Connected Load (Approximate): 40 kVA

Operating Voltage +10/-5%: 220, 3 Phase VAC

Operating Frequency: 24 V DC

CHIP CONVEYORS:

Magnetic Scraper-Type Conveyor (Standard): Ferrous Materials

'Smart' Hinge Chain Drum-Type Conveyor (Optional): Ferrous or Non-Ferrous Materials

'Smart-+' Hinge Chain Drum-Type Conveyor (Optional)*: Ferrous or Non-Ferrous Materials

* Incorporates Coolant Recovery Device.

MACHINE APPLICATION DETAILS & OPTIONS:

- Hobbing (axial, radial/axial) of spur and helical gears using one or multiple cut technology using climb or conventional feed with HSS or carbide hobs.

- Disc and shaft type workpieces.

- Spur and Helical Gears.

- Small Cone Gears.

- Cylindrical, Crowned or Tapered Gears.

- Special Profiles (Splines) with Special Tools.

- Worm (Wheel) Gear Hobbing.

- Tangential Hobbing Operation.

- Sprocket Hobbing.

- Ring Gear Hobbing.

- Multiple Gear / Stacking Hobbing.

*The above mentioned technical data may vary depending on the geometry of the workpiece to be machined and on the loading system and workholding fixtures used.

- This machine has been specifically developed for DRY hobbing operations and high speed cutting.

- This machine can be operated either DRY or WET with appropriate countermeasures; best to specify DRY or WET at time of order.

- Includes FULL Enclosure - Closed Top with opening for mist collector connection.

- Inner Stainless Steel Way Covers.

- Includes Hob Tool presetting station.

- Torque motor table design.

- Chiller Unit Integrated into Machine.

- Temperature Compensation is Standard.

- Central Lubrication System for all guideways and required positions. PLC controlled.

- Geared hob head with anti-backlash design.

- Skiving / Auto Stock Division Option Available.

- 2 or 4 Position Ring-Loader System Option Available.

- Optional Deburring / Chamfering Station Available.

- Optional Workpiece Stocking Systems / Conveyors Available.

- Robot Load Interface Option Available.

- Automatic Operator Door Option Available.

- Conversational Programming Standard - no need to know G or M Codes.

- Part Seat Confirmation System Available.

- Steady Rest Available - for Shaft-Type Parts Support in Tailstock.

- Coolant Oil Chiller Available.

- Minimum Quantity Lubrication Unit Available - for Dry Cutting.

- Disc-Type Pre-Deburring Device Available.

- Oil Mist Collector Available.

- X-Axis Linear Scale / Feedback System Available.

- Hob Tool Wear Monitoring System Available.

- Chamfer Cut Function (Fette Type) Available.

- Complete Workholding Systems Available.

- Complete Ancillary Automation Systems Available.

- Warranty Period - 1 Year Standard.

- Production Lead Time: 4 - 6 Months Dependent Upon Backlog at Time of Order.

U.S. Spec Machines will typically include the following:

- Standard Axial & Radial Travel Lengths.

- Magnetic Chip Conveyor & Coolant Tank.

- Hob Tool Presetting Station.

- Additional Items listed above in Specifications.

We use cookies to improve your experience. Privacy Policy.