IN STOCK, CAN BE CUSTOMIZED TO MEET SPECIFICATIONS.

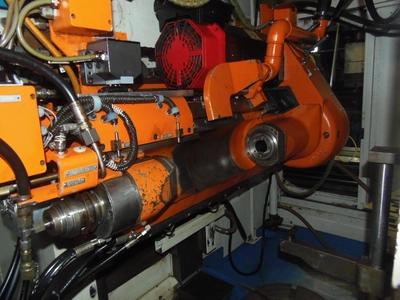

This machine was re-controlled by MTB with a Fanuc 18i-MA CNC and Fanuc Alpha series digital drives and motors in 2006 for a USA customer. In 2006 An entirely new electrical cabinet was installed along with all new equipment inside the electrical cabinet. In Roughly 2020 the machine was surplused and has been sitting idle since then. All support, service, parts and training are still available through Machine Tool Builders. Machine upgrades, software additions or other machine modifications or tooling that might be required are also available through Machine Tool Builders. The software in the machine is fully conversational based - so the simple question and answer format allows quick and easy programming of all spur and helical gears within the machine size and DP rating.

Mechanical Specifications:

Number of CNC controlled axes 5

Number of CNC controlled spindles 1

Pitch rating 4.23 DP 6 Mod

Maximum workpiece diameter 9.843 in 250 mm

Maximum axial travel 9.843 in 250 mm

Worktable diameter 9.843 in 250 mm

Worktable Worm Diameter 11.220 in 285 mm

Table bore diameter 3.937 in 100 mm

Maximum radial center distance 8.071 in 205 mm

Minimum radial center distance 0.787 in 20 mm

Maximum axial height from tabletop 15.354 in 390 mm

Minimum axial height from tabletop 5.512 in 140 mm

Maximum hob diameter 5.709 in 145 mm

Maximum hob length 9.055 in 230 mm

Maximum hob shift travel 6.693 in 170 mm

Maximum swivel angle -45 deg +45 deg

Hob speed range (Infinitely Variable) 48 to 480 RPM

Hob Spindle Power 10.7 HP 8 kW

Rapid traverse radial 118.110 in/min 3000 mm/min

Rapid traverse axial 78.740 in/min 2000 mm/min

Rapid traverse tangential 39.370 in/min 1000 mm/min

Machine Weight 14991 lbs. 6800 kg

Plant power 460 VAC 60 Hz

Features:

Tailstock with pressure adjustment

Power clamping with pressure adjustment

Controls

Fanuc 18i CNC

Fanuc Alpha Digital Servos

-----------------------------------------------------------------------------------------------------------------------

Three passes (same or alternating directions)

Hobbing of four sequential gears in one cycle

Inch / Metric switchable

Incremental shifting by part count

Crowning with high point offset capability

Taper compensation

Axial or radial/axial cycles

Radial only cycle

Programmable dwell

Automatic or manual overtravel and approach calculations

Tool offsets for quick size changes

Workpiece counter

Multiple program storage and retrieval

Shifting with table compensation

Auxiliary function selection (tailstock/clamping seq.)

Automatic or manual hob swivel angle calculation

We use cookies to improve your experience. Privacy Policy.