IN STOCK, READY FOR TEST CUTS!

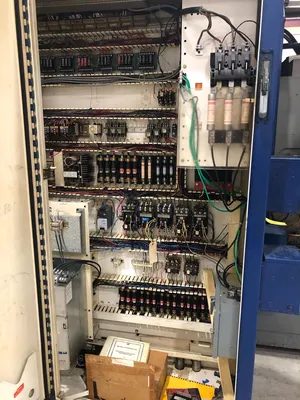

This machine was built at American Pfauter in the mid 1980's & equipped originally with an Allen Bradley 8200CNC, Bosch servo drives & motors, Heidenhain feedback systems and a Pfauter Geartronic for the Hob/Table/Helical/Tangential synchronization. In 2000, MTB retrofitted all the Bosch servos with new Indramat Ecodrives and an Indramat REFU drive for the spindle. The original Allen Bradley 8200 was retained but reprogrammed to accommodate the new servos. In this process some feedback systems were replaced by the new Indramat systems which utilize internal motor encoders. This machine has a motorized backlash free hob head powered by a liquid cooled AC Induction motor controlled by an Indramat REFU vector drive. It is also equipped with dual index drive worms for anti-backlash of the worktable and it features programmable power clamping and tailstock functions. It is equipped with 5 axes of servo motion and one spindle; "X" Radial, "Y" Tangential, "Z" Axial, "A" Hob Head Swivel, "C" Worktable. The hob rotation is technically the "B" axis, but it is also the spindle. This model is also equipped with a hydraulic retraction system in the event of a plant power failure while hobbing a workpiece. This feature withdraws the cutter with stored hydraulic energy at the instant of the power failure. Thus saving the cutting tool from damage and quite possibly your gear from damage as well. The machine does function as-is.

MTB currently has Allen-Bradley & Indramat parts to support this machine after the sale. The machine CAN BE re-controlled with new and updated CNC Controls System like a Fanuc, Siemens or NUM. This recontrol can occur at MTB before or after the sale, or later at a customer facility if so desired.

Number of CNC controlled axes 5: X, Y, Z, C, A

Number of CNC controlled spindles: 1

Pitch rating: 3.175 DP/8 Mod

Maximum hobbed diameter: (6″ cutter) 13.780 in 350 mm

Maximum hobbed/milled facewidth: 9.843 in 250 mm

Minimum axial height from table top: 8.268 in 210 mm

Maximum distance between centers: 10.433 in 265 mm

Maximum workpiece swing: 1.575 in 40 mm

Worktable diameter: 11.811 in 300 mm

Table bore diameter: 3.150 in 80 mm

Maximum radial center distance: 10.433 in 265 mm

Minimum radial center distance: 1.575 in 40 mm

Maximum hob diameter: 6.417 in 163 mm

Maximum hob length: 9.055 in 230 mm

Maximum hob shift travel: 6.693 in 170 mm

Maximum swivel angle: -40 deg 40 deg

Hob speed range (Infinitely Variable): 165 to 280 RPM

Hob Spindle Power: 20.1 HP 15 kW

Rapid traverse radial: 29.528 in/min 750 mm/min

Rapid traverse tangential: 29.528 in/min 750 mm/min

Rapid traverse axial: 29.528 in/min 750 mm/min

Length:181.102 in 4600 mm

Width: 116.142 in 2950 mm

Height: 101.575 in 2580 mm

Machine Weight: 20,723 lbs 9400 kg

Plant power: 480 VAC 60 Hz

Features:

Hydraulic Tailstock.

Automatic lubrication system.

Dual worm anti-backlash table drive.

Motorized hob head for heavy cutting.

Integral hydraulic unit for machine and hob carriage.

Sliding way covers for the axial axis.

Fully enclosed guarding around machine.

Hydraulic Retraction Function in case of Power Failure.

Coolant system.

Chip Conveyor.

One 1.25″ hob arbor and nut.

Two copies of the maintenance documentation.

Two copies of the operations manuals.

Two copies of the programming manuals.

30 Day return warranty on the machine.

Controls:

Allen Bradley 8200 CNC.

Indramat ECO Drives and REFU drive for Spindle.

Pfauter Z80 Geartronic for table control.

Base Software:

Conversational based platform within the CNC.

Automatic overtravel and approach calculations.

Auxiliary function selection (tailstock/clamping seq.).

Axial or radial/axial cycles.

Radial only cycle.

Crowning.

Inch / Metric switchable.

Incremental shifting by part count.

Multiple program storage and retrieval.

Programmable dwell.

Two passes (same or alternating directions).

Tool offsets for quick size changes.

Optional MTB Recertification Program (at Additional Cost):

Hob head will be checked for problems.

Work table drive system checked for problems.

Hydraulic system drained and cleaned.

All filters changed.

Polycarbonate guarding windows will be replaced.

Machine will be thoroughly cleaned.

All cycles will be tested and verified as fully functional.

All worn hoses replaced.

All broken electrical wires and cables will be repaired.

All defective controls will be replaced or repaired.

All features will be tested and verified as fully functional.

Coolant system checked for problems.

Coolant tank and chip collection system cleaned.

All axes checked for accuracy and repeatability.

All axes will be recalibrated for home positions.

Machine geometry checked and recorded.

Tuning of all axes servos will be verified and adjusted.

Sample parts will be cut if requested.

We use cookies to improve your experience. Privacy Policy.