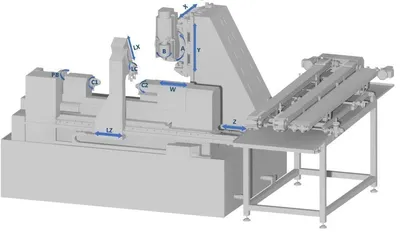

The Burri Model BZ 70 H gear grinding machine is the latest innovation from Burri with a remarkable portfolio of firsts. Horizontally oriented, this clean-sheet design is targeted towards small diameter planetary and sun gears through utilization of a very small mini grinding worm.

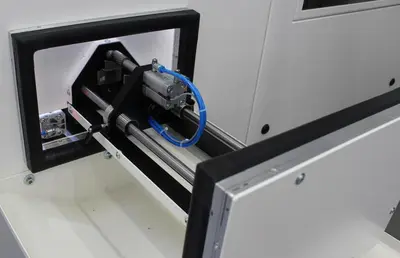

This design allows very fine adjustment of the tailstock center and incorporates two synchronous workpiece spindles to eliminate unstable rotating tailstock centers - guaranteeing more effective and concentric workholding during the grinding process.

The BZ 70 H is the first non-hydraulic gear grinding machine - the most energy efficient design on the market as well. Goodbye to hydraulic pump noise!

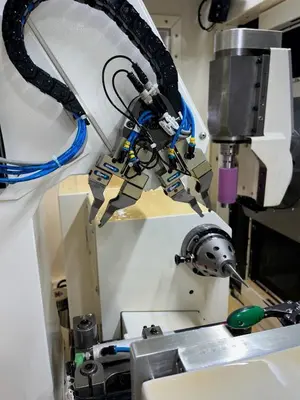

Capable of grinding solid (green) workpieces, this machine can solve real-world problems with hardened gears in automotive, aerospace, power transmission and the medical manufacturing sectors. Featuring Generating, Profile/Form or Worm Grinding capability, this machine will be outstanding for the fine pitch work in your facility!

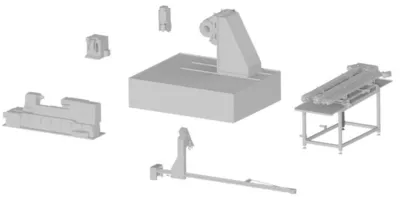

It can be configured with or without a loading system and is built to order.

Rebuilding & improving existing generating grinding machines is in Burri's DNA since 2002. Along the way, NEW machines were developed (such as the BZ 70 H!) along with rebuilds. Now there are more than 100 Burri machines sold and in operation throughout the world. Even mother machine builders use Burri for the more 'difficult' applications...

BZ 70 H GENERAL SPECIFICATIONS METRIC INCH

-----------------------------------------------------

Workpiece Diameter Minimum 00.00 mm 0.0000" (In Theory)

Workpiece Diameter Maximum 70.00 mm 2.7559"

Module Minimum 00.30 mm 84.6667 DP

Module Maximum 2.00 Mod 12.7000 DP

Helix Angle ±35 Degrees

Workpiece Overall Length 150 mm 5.9055 Inch (From Table to Tailstock)

Workpiece Weight Maximum 0.5 kg 1.1023 Lbs.

Workpiece Speed Maximum 4000 RPM

Grinding Pass Length 150 mm 5.9055"

Grinding wheel speed 80 m/sec 262.4672 ft/min

Grinding Wheel Max Diameter 120 mm 4.7244"

Grinding Wheel Max Width 120 mm 4.7244"

Dressing Disc Diameter Minimum 120 mm 4.7244"

Dressing Disc Diameter Maximum 140 mm 5.5118"

B&R Controls and Servos with Hybrid Systems - Motor & Encoder in one cable.

B&R Acopos-Multi Controller with Power Regeneration.

B&R Operating Panel with 21.5" Touch Screen Monitor.

Dittel wheel balancing system with integrated acoustic touch control.

Continuous Shifting during Grinding Process.

Profile & Lead Modifications.

Festo Pneumatic Componentry.

Machine Stack Signal Lamp.

B & C Axes are water-cooled integrated spindles.

Remote Diagnostics.

Conversational Programming.

Manual or Gantry Load.

Optional Part Stocking Magazine.

Generative Gear Grinding.

Twin Synchronized work spindles for ultimate accuracy.

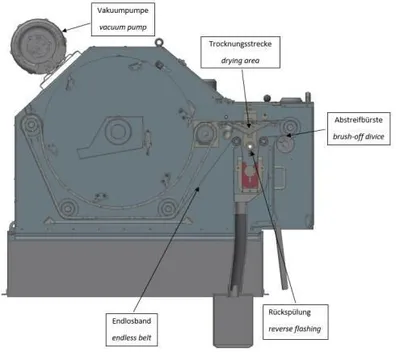

Coolant system w/Filtration & Chillers.

We use cookies to improve your experience. Privacy Policy.