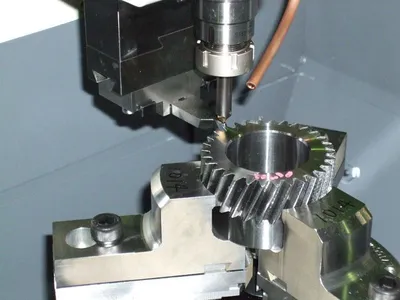

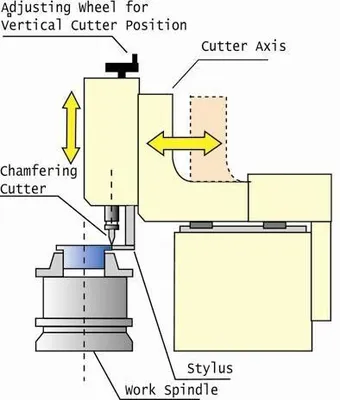

Senjo Seiki’s automatic chamfering machines are engineered for simplicity, accuracy, and durability. With this particular model, Senjo Seiki incorporates a patented stylus tracing method. The machine produces uniform chamfers without CNC programming. This process is ideal for gears and similar components, delivering consistent results with minimal setup that represents an ideal long sought after in the job-shop type environment.

Senjo Seiki has specialized in chamfering and deburring machines for more than 60 years and has delivered over 3,000 machines worldwide since introducing its program-less technology in 1997.

Key Features of this machine solution:

- Simple operation and quick setup.

- Consistent chamfers across the entire gear profile.

- Heavy-duty welded steel frame for long-term accuracy.

- Air-driven 3-jaw chuck for reliable clamping.

- Uses standard, off-the-shelf carbide endmills—no special tooling required.

- Full enclosure with automatic safety-interlocked door.

- Ergonomic operator controls for chamfer size, cutter, and spindle speed adjustments.

- Minimal readjustment required when changing to similar parts.

- PLC and inverter controls from Mitsubishi.

- Integrated coolant system with magnetic separator and oil skimmer.

Machine Specifications:

- Machine Type: Stand-alone, operator-loaded.

- Workpiece Capacity: Max. Ø8 in (200 mm), face width 4 in (100 mm).

- Chamfer Size: 0.04 x 0.04 in at 45°.

- Work Spindle Speed: 240–1,500 mm/min.

- Cutter Spindle Speed: Up to 12,000 rpm, adjustable.

- Cutting Tool: 90° V-shaped carbide endmill.

- Chuck: Air-driven 3-jaw automatic chuck.

- Control System: Mitsubishi PLC (FX series), inverter (S500 series).

- Safety: Keyence GL-R40H light curtain, 3-color signal tower.

- Motors: Cutter spindle (Oriental 5IK150A-TT2F), Work spindle (Oriental 5GE3S).

- Coolant System: Grundfos pump, Kanetec CMS-8 magnetic separator, Sogyo RB-200A oil skimmer.

- Power Supply: 3-phase, AC200V 50 Hz (via step-down transformer).

- Air Requirement: 0.4 MPa.

Included Standard Equipment:

- One vertical cutter spindle with digital Z-axis height adjustment.

- One part spindle with automatic air chucking unit.

- Touchscreen control panel and main electrical cabinet.

- Full enclosure with interlocked automatic front door.

- Coolant tank, step-down transformer, and 3-color signal tower.

- Two jig sets for part setup.

- Two sets of spare styluses.

- English-language manuals (electrical, mechanical, and operational).

- Pre-acceptance run at Senjo Seiki, Japan.

- One-year warranty.

We use cookies to improve your experience. Privacy Policy.