The Hamai N40 High-Rigidity (HR) horizontal gear hobbing machine (developed in 2024) is a refinement of the earlier Hamai N40 hobber first produced in 1988. Featuring a more robust design with more mass in the hob head, spindle and work table, these machines were developed to address challenging DRY cutting applications with high-hardness, heat treated materials. As a result of these new design features, the N40HR-DRY machine is rated with a higher Module size and is much more capable where DRY cutting is required using carbide hobbing tools. Featuring higher horsepower motors with greater torque, this machine pushes the envelope where tougher materials meet coarser pitches.

The N40HR-DRY machine comes configured with more standard components than it's earlier brother the Hamai N40 such as:

-6 Axes of CNC Control (see below for details).

-Standard A-Axis NC Control.

-More standard software features including lead crowning/taper forms.

Featuring direct-drive work and cutter spindles as well as optional synchronized counter spindles these machines are ideal for WET or DRY operations for cutting gears up to 1.25 Module / 20.32 DP. Coupled with the reliable Fanuc Series 31i CNC controls and drive system with conversational data input these machines are ideal for production & job shop environments.

Heavy duty design & construction make these machines absolutely ideal for high accuracy requirements on smaller gears. With various loading system options as well as optional skiving hobbing systems for hardened gears, these machines will be a welcome addition to your high-precision hobbing machine stable and will elevate your production to a whole new level.

Known for their heavy-duty construction, Hamai horizontal hobbers are known in tight circles for their high accuracy and stability in production applications. In many cases, gears are produced with similar AGMA quality levels as ground gears. As a stable platform for DRY cutting, these compact machines can be configured for dedicated or flexible production scenarios and can even be kitted out for skive hobbing of hardened gears.

The N40HR model is the BASE model and comes equipped for the US Market with Options added (and available Options) per below.

HAMAI N40HR SPECIFICATIONS:

MACHINE CAPACITY: METRIC INCH

Maximum Work Piece Diameter 40 mm 1.6 Inch

Max Work Piece Dia (w/32mm Hob) 20 mm 0.79"

Maximum Workpiece Length 50 mm 1.9"

Maximum Module 1.25 Module 20.32 DP

See "Working Ranges" (Below) for Additional Capacity Data.

WORK TABLE:

Minimum ~ Maximum Table Speed 10 RPM ~ 1000 RPM

Table Drive Power 2.4 kW 3.21 HP

Table Drive Torque 20 Nm 14.75 ft lbs.

Table Bore Diameter 15 mm

Table Outside Diameter 48 mm

HOB HEAD:

Maximum Hob Diameter 45 mm 1.8 Inch

Maximum Hob Length 50 mm 2.0 Inch

Minimum ~ Maximum Hob RPM 100 RPM ~ 6000 RPM

Hob Head Maximum Torque 6.4Nm 4.72 ft lbs.

Hob Spindle Power 10 kW 13.4 HP

Hob Arbor Diameter (STD) 10 mm 0.4"

Hob Arbor Diameter (OPT) 8 mm / 13mm - OR - Inch Sizes

Maximum Hob Shift Travel 50 mm 2.0"

Hob Swivel Angle (STD) ±45 Degrees

Hob Swivel Angle (OPT) +65/-25 Degrees

Hob Arbor Taper NT#20 Taper

WORKING RANGES:

X-AXIS:

Radial Minus / Plus limit 5 mm ~ 55 mm 0.2" ~ 2.2"

Total Radial Travel 50 mm 2.0"

Z-AXIS:

Axial Minus / Plus Limit 110 mm ~ 160 mm 4.3" ~ 6.3"

Axial Travel 50 mm 2.0"

Maximum Hobbed Length 75 mm 3.0"

TAILSTOCK:

Tailstock Minus / Plus limit 195 mm ~ 235 mm 7.7" ~ 9.25"

Tailstock Body Travel 40 mm 1.6"

Tailstock Quill Travel 40 mm 1.6"

Tailstock Force 1256 Nm 926 lb ft.

FEED RATES:

Radial (X) Cutting 0.1 ~ 500 mm/min 0.004 ~ 19.68"

Radial (X) Rapid 8 m/min 315.0 inch/min

Axial (Z) Cutting 0.1 ~ 500 mm/min 0.004 ~ 19.68"

Axial (Z) Rapid 8 m/min 315.0 inch/min

Tangential (Y) 3 m/min 118.1 inch/min

MISCELLANEOUS SPECIFICATIONS:

Number of axes 6 X = Radial Feed

Y = Hob Shift

Z = Axial Feed

A = Hob Head Swivel

B = Hob Spindle

C = Work Table

Number of Axes (OPT) 7 C2 = Tailstock Sync Counter Spindle

CNC Control Fanuc 31iMB

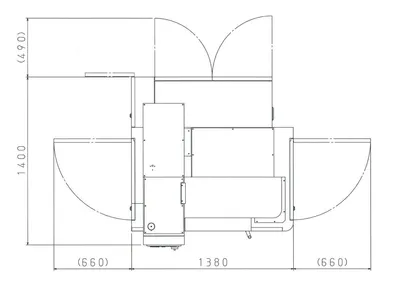

Machine Length 1400 mm 55.1 Inch

Machine Width 1380 mm 54.3 Inch

Machine Height 1865 mm 73.4 Inch

Machine Weight 1800 kg 3,968 lbs.

Voltage 200-220 VAC 3 Phase

Frequency 50/60 Hz

Load 8 kVA

AVAILABLE SOFTWARE / MACHINE FUNCTIONS:

One way cutting.

Double cutting (2 cycle).

Double cutting (conventional / climbing).

Crowning (Lead) cut.

Taper cutting.

Inch/Metric Switching/Conversion.

Automatic hob shift - both directions.

Working Hour / Working Counter.

Tailstock (Pressure Control).

Stored Program Memory - Maximum 53 pcs.

OPTIONAL MACHINE ITEMS (SPECIFIC TO APPLICATION):

Chip Conveyor for DRY Hobbing (in Lieu of WET - STD).

Chip Conveyor for DRY / WET Hobbing - for ability to switch types.

A-Axis Hob Head Swivel (NC Conversion) - specify ±45 Degrees - OR - +65/-25 Degrees.

X-Axis Retract Function - Power Failure Protection.

Hydraulically Actuated Deburring Slide System.

Tailstock Synchronized Counter Spindle (C2 Axis).

Electrical Cabinet A/C System.

Base N40HR Machine w/CNC Control - Fanuc 31i w/6 Axes of Control.

Automatic Lubrication System.

Automatic Hob Arbor Clamping System.

Full Machine Enclosure w/150mm Dia. Mist/Dust Collection Flange.

LED Lighting.

3 Color External Signal Lamp.

Mist Collector.

One Hob Arbor with Spacers.

Hob Arbor Counter Bearing Assembly.

Chip Conveyor for WET Hobbing.

Chip Box.

Oil Temperature Cooler (Chiller).

We use cookies to improve your experience. Privacy Policy.