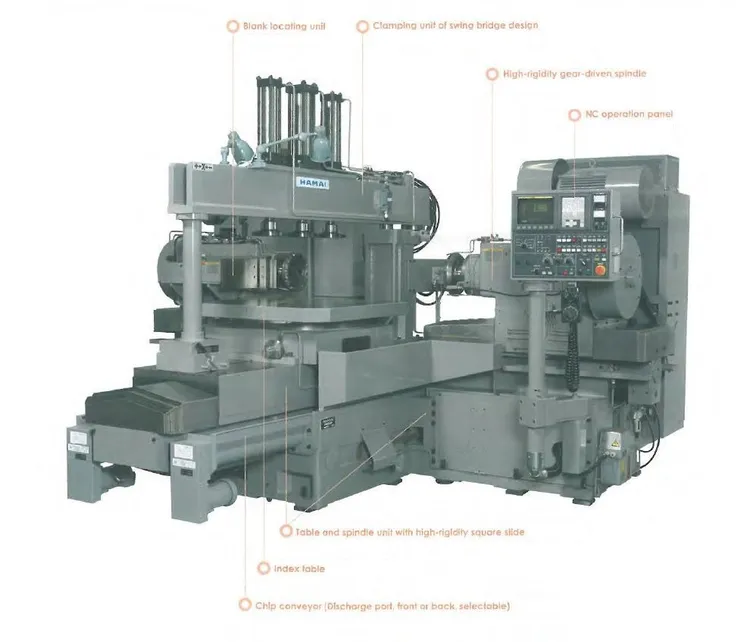

Hamai produces a unique 'Duplex,' or twin-sided milling machine series for specialty products. The Model 2DS-A has several examples installed in the United States and Hamai continues to build these highly accurate, 'niche' machine tools. These high-rigidity NC duplex milling machines with bridge-type clamping fixtures range from 310mm blank sizes all the way to 1,230mm.

HAMAI DUPLEX MILLING MACHINE MODEL #2DS-A SPECIFICATIONS & FEATURES:

-Moving the table between the opposed spindles ensures high parallelism between the workpieces.

-The slideway of each axis of constructed of hand-scraped box ways ensuring long-term accuracy.

-The index table is hydraulically driven and provided with a CURVIC coupling for high accuracy.

Additional Notes:

1) Machine power requirement: 200/220V-50Hz/60Hz-3Phases

Transformer: To be prepared by customer.

2) 250mm diameter cutter (R&L) to be prepared by customer.

3) Bore size of face mill is 1-7/8" (47.625mm) and 80mm thick.

X-Y axis work positioning device.

Measuring device.

AC inverter spindle 7.5 kw/11 kw in lieu of standard main motors.

Spindle load meter x 2 pcs.

Chip conveyor.

Centering plug (47.625 mm diameter x 32mm long) x 2 pcs.

Work light.

Air blow device.

Chamfering function at 45 degree.

Optional Equipment Included:

Index table 630mm (24.8") square, Max. work size : ロ700 x 200mm(H) (27.5 x 7.8").

Bridge type work clamping device with 1 cylinder.

We use cookies to improve your experience. Privacy Policy.