The Hamai Model N80L - Long Bed is the largest of the horizontal hobbing machines that Hamai produces with capabilities on workpieces of up to 80mm diameter with 500mm of maximum cutting length and 1000mm of maximum workpiece overall length.

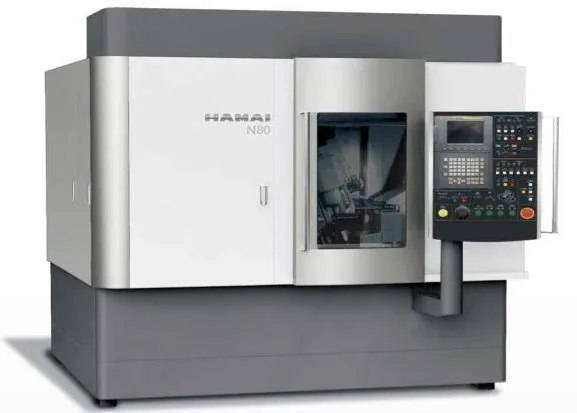

The N80 gear hobbing machine represents the largest machine that Hamai produces to date - having started producing them in 2005. The N80 is simply a larger machine for larger, coarser pitch gears with a LOT more room for flexible automation integration and customization. For DRY or WET cutting, this horizontal machine incorporates state of the art technology with (7) CNC axes driven by a Mitsubishi 31i Conversational CNC control.

Featuring direct drive work and cutter spindles this machine tackles dedicated or job type work with a number of installations in the world. Hamai of Japan has been producing high-precision horizontally-oriented hobbers since the early 1920's.

Heavy duty design & construction make these machines absolutely ideal for high accuracy requirements on smaller gears. With various loading system options as well as optional skiving hobbing systems for hardened gears, these machines will be a welcome addition to your high-precision hobbing machine stable and will elevate your production to a whole new level.

Known for their heavy-duty construction, Hamai horizontal hobbers are known in tight circles for their high accuracy and stability in production applications. In many cases, gears are produced with similar AGMA quality levels as ground gears. As a stable platform for DRY cutting, these compact machines can be configured for dedicated or flexible production scenarios and can even be kitted out for skive hobbing of hardened gears.

The N80 model is the BASE model and comes equipped for the US Market with Options added (and available Options) per below.

HAMAI N80L SPECIFICATIONS:

MACHINE CAPACITY: METRIC INCH

Maximum Work Piece Diameter 120 mm 4.7"

Maximum Work Piece Length 500 mm 19.68"

Maximum Module 3 Module 8.5 DP

See "Working Ranges" (Below) for Additional Capacity Data

WORK TABLE:

Minimum ~ Maximum Table Speed 10 RPM ~ 1000 RPM

Table Drive Power 6 kW 8.0 HP

Table Drive Torque 100 Nm 73.76 lb ft.

Table Bore Diameter 130 mm 5.118"

Table Outside Diameter 250 mm 9.84"

HOB HEAD:

Maximum Hob Diameter 80 mm 3.1"

Maximum Hob Length 120 mm 4.7"

Minimum ~ Maximum Hob RPM 200 RPM ~ 5000 RPM

Hob Arbor Diameter (STD) 16 mm 0.6"

Hob Arbor Diameter (OPT) 8 mm / 10 mm / 13 mm / - OR - Inch Sizes

Maximum Hob Travel (Y Axis) 100 mm 3.9"

Hob Swivel Angle ±45 Degrees

Hob Arbor Taper NT#30 Taper

Hob Spindle Power 15 kW 20.1 HP

WORKING RANGES:

X-AXIS:

Radial Minus / Plus limit 10 mm ~ 210 mm 0.4" ~ 8.27"

Total Radial Travel 200 mm 7.87"

Z-AXIS:

Axial Minus / Plus limit 200 mm ~ 700 mm 7.87" ~ 27.55"

Axial Travel 500 mm 19.68"

Maximum Hobbed Length 500 mm 19.68"

TAILSTOCK:

Tailstock Minus / Plus limit 400 mm ~ 1600 mm 15.74" ~ 63"

Tailstock Body Travel 1200 mm 47.24"

Tailstock Force 100 Nm ~ 4,500 Nm 74 ~ 3,320 lb ft.

FEED RATES:

Radial (X) Cutting 0.1 ~ 500 mm/min 0.004 ~ 19.68"

Radial (X) Rapid 6 m/min 236.2 inch/min

Axial (Z) Cutting 0.1 ~ 500 mm/min 0.004 ~ 19.68"

Axial (Z) Rapid 6 m/min 236.2 inch/min

Tangential (Y) Cutting 0.1 ~ 500 mm/min 0.004 ~ 19.68"

Tangential (Y) Rapid 3 m/min 118.1 inch/min

MISCELLANEOUS SPECIFICATIONS:

CNC Fanuc 31i-MB

Number of axes 7 X = Radial Feed

Y = Hob Shift

Z = Axial Feed

A = Hob Head Swivel

B = Hob Spindle

C = Work Table

W = Tail Stock

Length 2200 mm 86.6"

Width 2300 mm 90.6"

Height 2200 mm 86.6"

Weight 5500 kg 12,125 lbs.

Voltage 230 VAC 3 Phase

Frequency 50/60 Hz

Load 24 kVA

AVAILABLE SOFTWARE / MACHINE FUNCTIONS:

Hob spindle & worktable positioning.

Multiple gears - up to 4 different data sets.

Automatic workpiece safety - prevents cutting workpiece twice.

One way cutting.

Double cutting (2 cycle).

Double cutting (conventional / climbing).

Crowning (Lead) cut.

Taper cutting.

Inch/Metric Switching/Conversion.

Automatic hob shift - both directions.

Working Hour / Working Counter.

Tailstock (Pressure Control).

Stored Program Memory - Maximum 39 pcs.

Hob Tool Wear & Breakage Monitoring.

OPTIONAL MACHINE ITEMS (SPECIFIC TO APPLICATION):

Chip Conveyor for DRY Hobbing (in Lieu of WET - STD).

Chip Conveyor for DRY / WET Hobbing - for ability to switch types.

5C Collet Adaptation System.

A-Axis Hob Head Swivel - specify ±45 Degrees - OR - +65/-25 Degrees.

X-Axis Retract Function - Power Failure Protection.

Hydraulically Actuated Deburring Slide System.

Electrical Cabinet A/C System.

Auto Door Device.

Automation / Robot Integration.

Base N80L Machine w/CNC Control - Fanuc 31i w/7 Axes of Control.

Automatic Lubrication System.

Automatic Hob Arbor Clamping System.

Full Machine Enclosure w/150mm Dia. Mist/Dust Collection Flange.

LED Lighting.

3 Color External Signal Lamp.

Mist Collector.

One Hob Arbor with Spacers.

Hob Arbor Counter Bearing Assembly.

Chip Conveyor or WET Hobbing.

Chip Box.

Oil Temperature Cooler (Chiller).

Electrical Cabinet A/C System.

We use cookies to improve your experience. Privacy Policy.