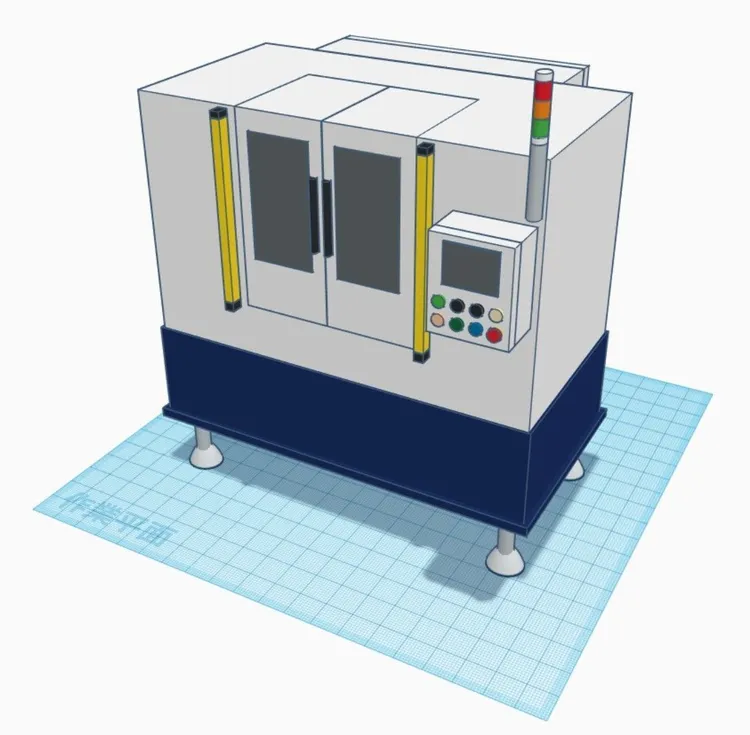

Senjo Seiki Automatic Tooth Chamfering Machine - Stylus Tracing Method - Outside Diameter Workpieces up to Maximum Diameter of 39" / 1000mm.

- Simple operation and set-up.

- Generates consistent chamfers through part profile with standard 'off the shelf' cutting tools.

- Standard type tooling is used from Carbide endmills mounted in the collet spindle and air driven power chucks. Consequently, replacement and replenishment of tooling does not require special orders which can be costly and have long lead times.

- Machine completely enclosed with interlocked safety features.

- Machine requires NO programming experience to operate.

- Due to the unique design and the use of a stylus tracing system, the process of generating a consistent chamfer is completed without the need for any computer programming and can be generated on most gears and other components.

- When clamping the work piece in the machine, radial positioning and concentricity of the part are not required as in other manufacturer’s processes. The cutter axis moves forward and backward by simply following the outer shape of the component, so that even if the component is changed, it may not be necessary to readjust.

- Rigid Construction for Long Term featuring fabricated steel base with componentry purchased from internationally recognized (known) manufacturers.

- The chamfer size, cutter spindle and work spindle rotational speeds can be easily adjusted using the ergonomically placed controls. As long as key requirements for a new component are similar to the previous component, the new component can be chamfered by the machine with minimal adjustments.

MACHINE SPECIFICATIONS:

Machine Type: Stand Alone, Fully Enclosed w/Safety Interlocks

Loading/ Unloading: Manually Loaded by Operator

Machine Cover: Machine Covers w/ Interlocked Front Door & Side Door (for Maintenance and Change-Over)

PLC: Mitsubishi (FX-Series)

Inverter: Mitsubishi (S500 Series)

Counter: Yes, displayed on Touch Screen

Signal Tower: 3 colors

Safety Light: LED Light Inside Enclosure

Light Curtain: Keyence (GL-R40H)

Motors: Cutter Spindle: Oriental (5IK150A-TT2F)

Work Spindle: Oriental (5GE3S)

Coolant System Pump: MTA60-180-A-W-A-T (GRUNDFOS)

Magnetic Separator: CMS-8 (Kanetec)

Oil Skimmer: RB-200A (Sogyo)

Part Diameter Range: O/D= Max. Dia. 39”

Gear Face Width Max.: 4”

Chamfer Size: 0.04” x 0.04”, 45deg

Part Name / Number: Gears

Work Spindle Traverse: 240 – 1,500 (mm/min)

Cutter Spindle Speed: Max 12,000 rpm (Adjustable)

Cutting Tool: 90deg V-Shaped Carbide Endmill

Power Supply: 3 phase, AC200V, 50Hz (Use Step-down-Transformer)

Air Supply Required: 0.4mpa

STANDARD FEATURES INCLUDED:

-Two (2) Vertical Cutter Spindle with AC Servo Height Control

-One (1) Part Rotating Axis with Part Chucking Unit

-Touch Screen Control Panel

-Main Electrical Cabinet

-Machine Covers w/ Interlocked Front Door & Side Door (for Maintenance & Change-Over)

-Coolant Tank

-Signal Tower (3-Colors)

-Step-Down Transformer

-Two (2) Types of Jigs and Adjustments (Part Touching Detail)

-Two (2) Sets of English Language Electrical, Operational, and Mechanical Manuals

-Two (2) Sets of Spare Styluses

-Machine Pre-Acceptance at SENJO SEIKI, Japan

-Machine Installation & Trainings at CAT Solar Turbine

-Machine 1 Year Warranty

-Machine Quoted FOB Dock - Subject to review at time of order to due Customs/Clearance/Shipping Charges in effect at time of order AND at time of receipt.

We use cookies to improve your experience. Privacy Policy.