Gleason-Pfauter P400/600G Form Gear Grinder — Recertified & Re-Controlled by Machine Tool Builders.

The Gleason-Pfauter PE725G is effectively a 'stretched' model P400/600G. This machine is a heavy, rigid, and extraordinarily capable form gear grinder—well suited for high-accuracy production of spur and helical gears, pinions, shafts, splines, and similar profiles using vitrified or CBN grinding wheels.* This machine is being fully recertified and re-controlled by Machine Tool Builders, incorporating MTB’s latest grinding technology platform, conversational form-grinding software, optional on-board inspection, integrated wheel dressing, and our Electronic Setup Assistant (MESA). Once complete, the machine will be delivered ready for immediate precision production.

* This machine is currently set up without a dressing system. Based on customer demand, a dressing system will be applied at time of build.

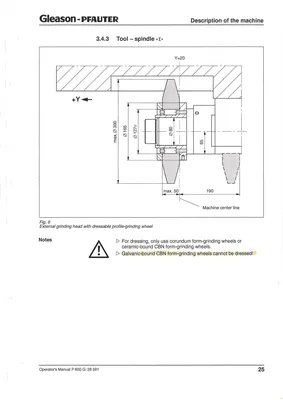

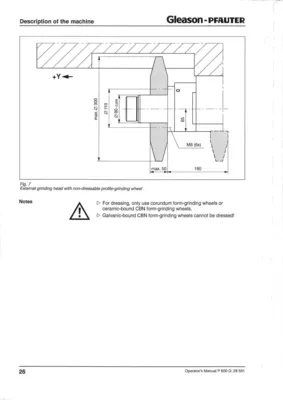

Grinding Spindles & Wheel Options:

The standard wheel spindle accepts 250 mm OD wheels with a 76.2 mm arbor. Optional spindles—127 mm arbor (300 mm wheel) and 50.8 mm arbor (200 mm wheel)—may be available pending confirmation.

Wheel changes typically require less than five minutes. Spindle changes take longer, so MTB generally recommends selecting a single common spindle size for all grinding wheels to streamline workflow and lower tooling overhead.

Control Platforms & Options:

• Pfauter PE725G base platforms.

• Siemens or Fanuc controls (inspection Siemens-only).

• Marposs high-accuracy scanning probe or equivalent.

• Configurable tooling, workholding, probing, and wheel packages.

Machine Highlights — MTB New Grinding Technology:

Form Grinding.

• Spur & helical gears.

• Single-flank or optional double-flank grinding.

• Lead modifications.

• Profile modifications.

• Independent left/right flank data.

• Special geometrical modifications.

On-Board Wheel Dressing:

• Tip-relief straight/parabolic.

• Profile crowning.

• Root radius / fillet shaping.

• Point-by-point profile corrections.

• Independent left/right flank dressing.

• User-defined special dressing functions.

Optional On-Board Inspection (Siemens Only):

• Profile.

• Lead.

• Index / pitch variation / spacing / accumulative error / runout.

• Tooth size (thickness, DOP, span measurement).

• Stock division.

• AGMA/DIN/ISO tolerance analysis.

• Probe calibration without interrupting grinder setup.

MTB Electronic Setup Assistant (MESA):

• Built-in algorithms for automatic setup optimization.

• Profile, lead, and tooth-size recommendations.

• Operator can accept, modify, or reject suggestions.

Human-Machine Interface:

• Intuitive, visual interface reducing training time.

• Unified navigation linking Grinding, Dressing, Inspection, and Setup.

• Minimal required data entry with smart defaults.

• Quick access to all screens.

• Real-time validation of gear geometry and dressing data.

• Metric/Inch switching at any time.

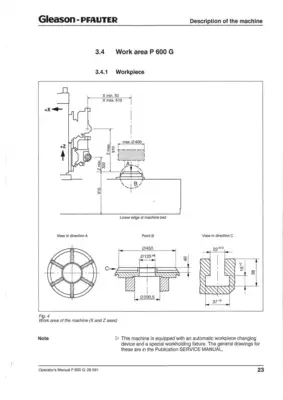

Machine Tool Builders Pfauter PE725G form grinder CNC Recontrol & Recertification Program. Workpiece / Tool / Machine Specifications:

Some specifications subject to change per ongoing build parameters.

Description Inch Metric

Maximum form-grinding wheel diameter 11.81 in 300 mm

Maximum wheel width 1.57 in 40 mm

Spindle journal diameter 3.15 in 80 mm

Spindle journal length 5.20 in 132 mm

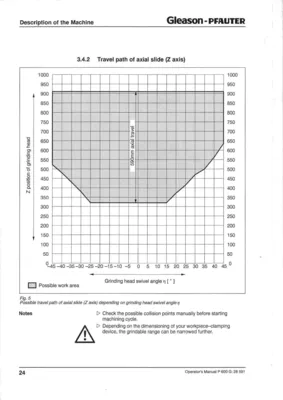

Axis Travel Distances:

Description Inch Metric

Radial travel (X-axis) 22.05 in 560 mm

Tangential travel (Y-axis) 7.68 in 195 mm

Axial travel (Z-axis) 23.23 in 590 mm

Grinding Head Pivoting

Description Inch Metric

Pivot +A direction — +40°

Pivot –A direction — –40°

Worktable:

Description Inch Metric

External table diameter 17.72 in 450 mm

Table bore diameter 4.92 in 125 mm

Maximum table load — 12 kN

Machine Dimensions & Weight:

Description Inch Metric

Overall length 360.04 in 9,165 mm

Overall width 298.43 in 7,580 mm

Overall height 194.88 in 4,950 mm

Machine weight (approx.) 24,250 lb 11,000 kg

Feeds, Rapid Traverses & Speeds:

Axes Feeds / Rapids

Description Inch Metric

X-axis feed / rapid 118.11 in/min 3,000 mm/min

Y-axis feed / rapid 196.85 in/min 5,000 mm/min

Z-axis feed / rapid 188.98 in/min 4,800 mm/min

Speeds:

Description Inch Metric

Tool spindle speed range 1 — 1,200–8,000 rpm

Tool spindle speed range 2 — 1,000–10,000 rpm

Worktable (C-axis) speed — 0–22 rpm

Electrical Specifications:

Description Inch Metric

Operating voltage — 460 V

Supply voltage — 230 V

Control voltage — 24 V

Frequency — 60 Hz

Cable cross-section — 35 mm²

Circuit protection — 100 A

Connected load — 70 kVA

Dressing System – Technical Data:

NOTE: Machine is currently configured for CBN operation only. A dressing system For vitrified operation will be sourced based on customer demand..

Dressing Axis Travel:

Description Inch Metric

Z2-axis travel 5.91 in 150 mm

Dressing Axis Feeds / Rapids

Description Inch Metric

Z2 axis feed / rapid 196.85 in/min 5,000 mm/min

Dressing Spindle Speed

Description Inch Metric

Dressing spindle (S2) — 3,000–8,000 rpm

Dressing Wheel Dimensions

Description Inch Metric

Maximum dressing wheel diameter 5.91 in 150 mm

We use cookies to improve your experience. Privacy Policy.