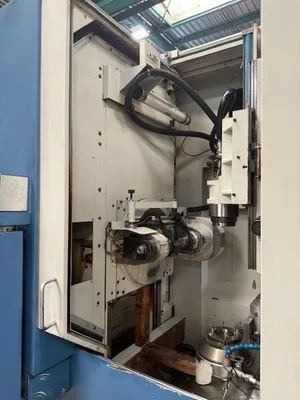

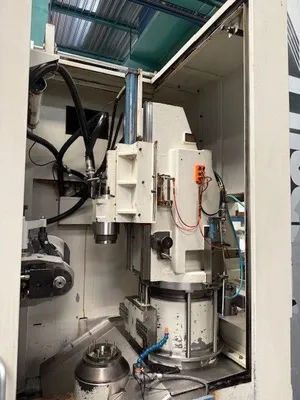

This 400 mm-class CNC hobber carries forward the Gleason legacy of rigid construction and forward-looking engineering. High-speed capability, robust castings, and modern design principles give it the backbone to fully exploit today’s—and tomorrow’s—cutting tool technology. The PHOENIX 400GH keeps its footprint compact without compromising rigidity, accuracy, or serviceability, and its use of standardized, globally supported components helps ensure quick delivery, lower maintenance, and minimal spare-parts burden.

Built-in thermal stability and Gleason’s mature CNC software platform deliver excellent accuracy and repeatability while keeping operating costs in check. The machine supports both wet and dry hobbing and handles high-speed steel or carbide tooling with ease.

Gleason’s CNC hobbers have long been benchmarks in the industry; the 400GH builds on that lineage. It’s engineered for straight spur and helical gears, pinions, splines, worm gears, and similar profiles up to 400/450 mm (15.75/17.72 in) diameter, 525 mm (20.67 in) face width, and 2.5 DP capability.

The machine is equipped with a FANUC 150MB control featuring color CRT, conversational English dialogue, and automatic setup across six controlled axes, with all parameters available in inch or metric.

This 400GH is currently on the floor at Machine Tool Builders in Machesney Park, IL. It is expected to be under power and available for demonstration—and ultimately shipment to a client—near the end of February 2026.

Gleason PHOENIX 400GH — Consolidated Specification Sheet

DESCRIPTION — INCH / ENGLISH — METRIC

CAPACITY & RANGE:

Maximum workpiece diameter — with carousel 15.75" 400 mm

Maximum workpiece diameter — manual load 17.72" 450 mm

Maximum part weight (carousel) 125 lbs 56 kg

Max diametral pitch / module (standard 100–1000 RPM) 2 NDP 12 module

Max diametral pitch / module (optional 150–1500 RPM) 2.5 NDP 10 module

Maximum hob spindle torque 2500 in-lb 280 Nm

Maximum hob setting angle ±45° ±45°

Total swivel motion –165° / +45° (210°) –165° / +45° (210°)

Minimum number of teeth 2 2

SPINDLE, TABLE & SLIDE GEOMETRY:

Center distance Hob → Workpiece (min) 1.38" 35 mm

Center distance Hob → Workpiece (max) 12.20" 310 mm

Height Work spindle → Hob center (min) 2.95" 75 mm

Height Work spindle → Hob center (max) 9.25" 235 mm

Axial hob slide travel 10.82" 275 mm

Radial slide travel 10.83" 275 mm

Work spindle → Tailstock face (min) 13.78" 350 mm

Workspindle → Tailstock face (max) 14.96" 380 mm

Work spindle mounting diameter (with adapter) 5.91"–12.60" 150–320 mm

Draw rod interface hole diameter 5.98" 152 mm

Work spindle bolt circles 5.91" & 7.48" 150 & 190 mm

Tapped holes M10 × 1.5 × 20 mm M10 × 1.5 × 20 mm

Max chucking force (hydraulic) 17,600 lbf 78.3 kN

HOBBING TOOLING & DRIVE:

Maximum hob diameter 6.25" 160 mm

Maximum hob length (tangential travel) 4.88" 460 mm (varies; 50 mm min)

Hob arbor diameters (Available, not necessarily present) 1.25" / 1.50" 32 / 40 mm

Hob spindle taper ISO 40

Hob spindle speeds — standard: 150–1000 RPM 150–1000 RPM

Hob spindle speeds — optional: 150–1500 RPM 150–1500 RPM

Low-speed range: 1–75 RPM

Optional low-speed: 15–150 RPM

FEED RATES, MOTORS & POWER:

Worktable speed 197"/min 5000 mm/min

Radial traverse rate 197"/min 5000 mm/min

Axial traverse rate 197"/min 5000 mm/min

Hob drive motor (6000 RPM, 15 Alpha) 20 HP 15 kW

Work spindle motor 10 HP 7.5 kW

Hydraulic unit motor 3 HP 2.2 kW

Coolant motor — high pressure 11 HP 8 kW

Mist collector motor 0.75 HP 0.6 kW

DIMENSIONS & WEIGHT:

Machine size 93" × 134" 2.36 × 3.40 m

Machine w/ carousel (approx.) 198" × 206" 5.8 × 7.2 m

Net machine weight 26,200 lbs 11,884 kg

Net weight w/ carousel 26,600 lbs 12,128 kg

FEATURES & EQUIPMENT:

• Machine-mounted, air-conditioned electrical enclosure with operator controls at front.

• Fully enclosed work area with powered operator access door and internal lighting.

• Smoke/mist collector interface.

• Self-contained coolant system with tank, pump, piping, magnetic chip conveyor.

• Cooler-chiller for both hydraulic and cutting oil circuits.

• Standard swivel hob head with FANUC 15 motor and quick-change hob clamping.

• One hob arbor (diameter specified by customer).

• Hydraulic workpiece chucking via draw-arbor.

• Support column & hydraulic tailstock arm with 180° swivel base for twin-gripper load/unload.

• Pallet/carousel system with sixteen (16) adjustable workpiece pallets (outside enclosure).

• FANUC 150MB CNC with color CRT, English conversational programming, inch/metric display.

• CNC control of six axes:

– (A) - axial feed

– (X) - radial feed

– (Y) - hob position

– (S) - hob speed

– (C) - worktable

– (A) - swivel angle

• Software supports With user friendly conversational dialog in English, values displayed for both inch and metric with programs for the following in various combinations: radial/axial hobbing, climb & conventional hobbing, crowning, taper hobbing, single/multi-cut cycles, shift strategies, single-index milling/hobbing.

• Edit summary data while in cycle.

• Integrated fault diagnostics.

• Program storage for 100 parts.

• Setup security key.

• Full electrics for 380V / 50 Hz.

• Complete machine documentation: manuals, parts list, hydraulic & electrical schematics.

PRINCIPAL SPECIFICATIONS:

Max workpiece dia. — carousel 15.75" 400 mm

Max workpiece dia. — manual 17.72" 450 mm

Max weight — carousel 125 lbs 60 kg

Max DP (standard) 2 NDP 12 module

Max DP (optional) 2.5 NDP 10 module

Max hob spindle torque 2500 in-lb 280 Nm

Max hob setting angle –165° / +45° –165° / +45°

Min number of teeth 2 2

Max center distance (hob ↔ work) 12.20" 310 mm

Min center distance (hob ↔ work) 1.38" 35 mm

Max height (table → hob ctr) 23.82" 600 mm

Min height (table → hob ctr) 2.95" 75 mm

Max axial hob slide 20.67" 525 mm

Max radial slide 10.83" 275 mm

Max distance table → tailstock 33.47" 850 mm

Min distance table → tailstock 13.78" 350 mm

Worktable mounting dia. 8.66" 220 mm

Worktable mounting dia. w/ adapter 14.96" 380 mm

Work spindle taper Gleason #50 Gleason #50

Taper bore depth 5.98" 152 mm

Bolt circles 5.91" & 7.48" 150 & 190 mm

Tapped holes M10 × 1.5 × 20 mm M10 × 1.5 × 20 mm

Max chucking force 17,600 lbf 78.3 kN

Max hob diameter 6.3" 160 mm

Max hob length 9.5" 240 mm

Max hob shift 8.66" 220 mm

Hob arbor diameters 1.25", 1.50", 2" 32, 40, 50 mm

Hob spindle taper ISO 40 ISO 40

Hob speed range 100–1000 RPM 100–1000 RPM

Work spindle speed 1–75 RPM 1–75 RPM

Rapid traverse (axial) 197"/min 5000 mm/min

Rapid traverse (radial) 197"/min 5000 mm/min

Hob drive motor 20.1 HP 15 kW

Hydraulic pump motor 5 HP 3.7 kW

Hydraulic capacity 10 GPM 38 L/min

Overall height (no collector) 117" 2970 mm

Overall height (with collector) 129.5" 3290 mm

Floor space — manual load 79" × 114" (62 ft²) 1996 × 2890 mm (5.8 m²)

Floor space — carousel 79" × 133" (72 ft²) 1996 × 3363 mm (6.7 m²)

Net weight (no carousel) 26,000 lbs 11,820 kg

Net weight (w/ carousel) 26,800 lbs 12,188 kg

We use cookies to improve your experience. Privacy Policy.