Lorenz LFS-424 CNC Gear Shaping Machine — Recertified & Fanuc-Recontrolled by MTB.

The Lorenz LFS-424 is a heavy-duty, high-precision CNC gear shaping machine engineered on Lorenz’s well-known foundation of rigidity, accuracy, and mechanical longevity. This machine is equipped with both a tailstock and a power clamping cylinder, giving it excellent stability and versatility for internal and external shaping work across the full 420-mm class.

This LFS-424 is currently on our shop floor undergoing MTB’s full recertification program. That process includes a complete mechanical and functional inspection, fresh paint and cosmetic restoration, and a comprehensive Fanuc CNC recontrol. When complete, the machine will be delivered in a condition suitable for seamless entry into production.

This machine has an included tail stock and power clamping cylinder in the table.

The machine is presently slated for completion in roughly three to four months, though the schedule can be accelerated depending on program requirements—just reach out and we can coordinate.

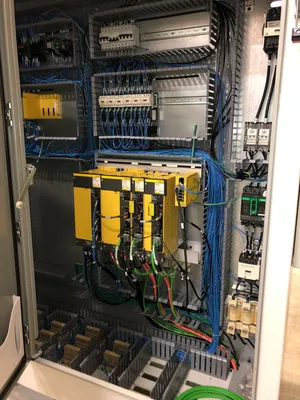

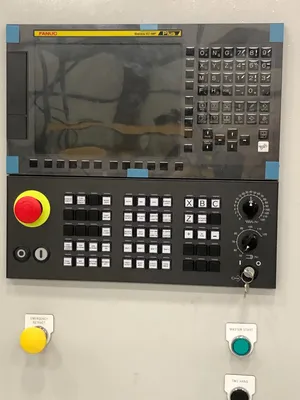

The CNC system is being upgraded to a modern Fanuc 0i-MF Plus control package, supported by new Fanuc Alpha HVi digital servomotors and drives and a full Fanuc Alpha-series spindle drive system. An all-new electrical cabinet is being installed, complete with new wiring where needed and all-new industrial components: motors, starters, relays, power supplies, contactors, terminal strips, and fuses. The machine will ship with MTB’s well-proven conversational shaping software, providing intuitive, menu-driven screens for setup, tooling input, and part-program recall—cutting setup time while improving consistency.

The shaping spindle incorporates a servo-controlled orienting system with precise positioning to TDC and BDC, complete with positive confirmation of arrival. Elevation and stroke length share a common servo motor but are monitored with independent feedback systems to maintain accuracy throughout the full allowable stroke range.

Once recertification and recontrol are complete, this Lorenz LFS-424 will offer a rare combination of German mechanical integrity and a modern, serviceable Fanuc CNC platform. It represents a robust, highly capable 420-mm class shaping machine that delivers dependable performance, straightforward operation, and the long-term maintainability that defines MTB’s rebuild philosophy.

For manufacturers needing a powerful, production-ready CNC shaper backed by a team that services everything it sells, this machine is an exceptional choice.

**Lorenz LS-424 CNC Gear Shaping Machine (Recertified & Fully Recontroled by Machine Tool Builders, Inc.)**

Machine Specifications:

CNC System & Power:

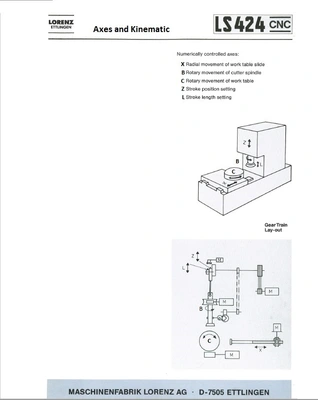

Number of CNC-controlled axes: 5

Number of CNC-controlled spindles: 1

All principal motions on the Lorenz LFS-424 will be fully controlled by the Fanuc CNC:

• 'X' – Radial movement of the worktable slide

• 'B' – Rotary cutter spindle

• 'C' – Rotary worktable

• 'Z' – Stroke position setting

• 'L' – Stroke length setting

Spindle power: 20.1 HP / 15 kW

Plant power: 460 VAC, 60 Hz

Load: 72 FLA

Disconnect rating: 100 A

Primary control voltages: 24 VDC, 120 VAC

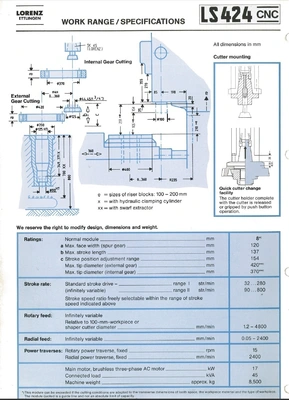

Pitch Capacity:

Diametral Pitch: 3.18 DP

Module: 8 mod

Workpiece & Travel Capacity:

Max. external workpiece diameter: 16.535 in / 420 mm

Max. internal workpiece diameter: 14.567 in / 370 mm

Max. axial travel: 6.063 in / 154 mm

Max. radial center distance: 14.0 in / 355 mm

Min. radial center distance: –0.2756 in / –7 mm

Max. axial height from table: 18.3209 in / 465.350 mm

Min. axial height from table: 12.2578 in / 311.348 mm

Maximum face width: 4.724 in / 120 mm

Maximum stroke length: 5.393 in / 137 mm

Following Riser Data may affect capacities above; please correspond with us and watch this space further for additional data.

Riser Height (installed): 3.937 in / 100 mm

*Riser Height (optional): 7.87 in / 200 mm

Table, Cutter & Construction:

Worktable diameter: 15.748 in / 400 mm

Table bore: 4.921 in / 125 mm

Cutter spindle diameter: 3.937 in / 100 mm

Speeds & Feeds:

Stroking speed range: 100–800 SPM

Radial feed (inch): 0.0001–59.055 in/min

Radial feed (metric): 0.001–1500 mm/min

Rotary feed at 18" dia: 0.0001–56.69 in/min

Rotary feed at 458 mm dia: 0.001–1440 mm/min

Rapid traverse (radial): 59.055 in/min / 1500 mm/min

Rapid traverse (axial): 118.110 in/min / 3000 mm/min

Rapid cutter traverse: 1440 deg/min / 4 RPM

Rapid table traverse: 1440 deg/min / 4 RPM

Weight:

Machine weight: 18,739 lbs / 8,500 kg

Scope of Work & Recertification Summary:

General:

All work performed by Machine Tool Builders, Inc.

Full CNC recontrol with new FANUC system, new drives, new motors, new wiring, and a new electrical cabinet.

Machine, cabinet, guarding cleaned and repainted.

Complete mechanical and functional inspection.

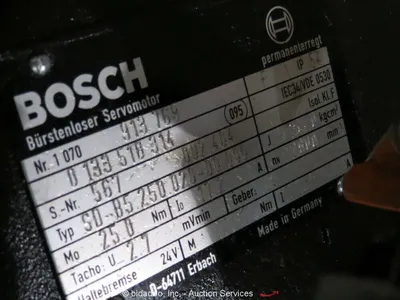

Axes & Motors:

New servo motors installed on:

X axis

Z/L axis (elevation & stroke)

B axis (cutter spindle)

C axis (work spindle)

New Fanuc spindle drive and spindle motor.

Mechanical:

Motor flange, coupling, and pulley engineering & fabrication.

Removal of old servos and installation of new.

No major mechanical repairs unless required.

MTB will advise if mechanical issues arise — Notation.

Shaping Head:

Fully inspected; repairs only if necessary — Notation.

Worktable:

Fully inspected; repairs only if required — Notation.

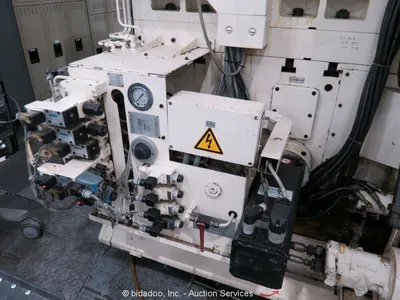

Hydraulic System:

CNC interfaced to existing hydraulics.

New hydraulic hoses installed – Notation.

Lubrication:

CNC interfaced to existing lubrication system.

Issues will be reported if found – Notation

Coolant:

CNC interfaced to existing coolant system.

Chip Extraction:

CNC interfaced to existing chip extraction.

Electrical:

New electrical cabinet with all new IEC components.

New operator station.

Wiring inspected & repaired; reconnect via terminal strip.

All wire, conduit, flex, labels provided.

Electrical prints and parts lists generated in AutoCAD Electrical.

New servo power, feedback, and scale cabling.

Use of absolute encoders wherever applicable.

--------------------------------------------------------------

New absolute scale installed if an axis previously used a scale – Included

Power requirement: 460 VAC, 60 Hz – Included

If the plant does not use a grounded wye system, isolation transformer required — Notation

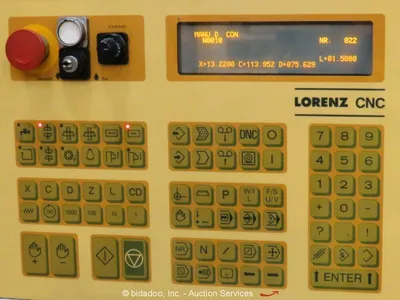

Controls

New Fanuc 0i-MF Plus CNC with 10.4" horizontal display – Included

Fanuc Alpha HVi digital servo drives & motors – Included

Fanuc Alpha HVi spindle drive & motor – Included

Shaping Software (MTB Conversational Platform)

Up to four sequential surfaces

Up to five cuts per cycle

Spiral or plunge infeed

Programmable rotary dwell

Digressive infeed

Inch/metric switchable

Spiral out of cut

Full M & G-code capability

Quick recut cycle

Automatic cutter indexing

Cutter & workpiece orientation

Clamp avoidance

Tailstock/clamping auxiliary sequencing

Slotting capability

Programmable elevation (range dependent on stroke)

Painting:

Machine and ancillary equipment refinished – Included

Tooling:

One cutter adapter, size and type TBD – Included

Documentation:

(2) Sets wiring diagrams (11×17)

(2) Operator manuals

(2) Spare parts & service manuals

(2) Copies PLC logic, plus backup media

(2) Sets of mechanical prints for MTB-made changes

Standards Compliance:

Electrical, mechanical, hydraulic, pneumatic, and safety work completed per ISO, IEEE, ANSI, DIN, NFPA, and customer specifications – Included

Options:

Cutter adapters: priced upon specification – TBD

Tailstock: dependent on design requirements – One is included (see pictures).

We use cookies to improve your experience. Privacy Policy.