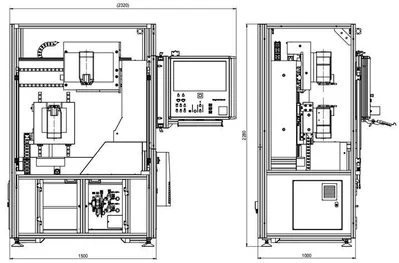

Geartec.CZ - External Gear Measuring Machine – Single Flank Inspection – Motorized – for Spur & Helical Gears.

This machine is exclusively designed for the measurement of external gears using the single-flank inspection method. It is based on Geartec.CZ's Model #GTB100 Single Flank Measuring System, incorporating the newest generation of precision technology.

Mechanical Design:

The main body of the machine is constructed from a solid, high-stability granite bed, ensuring excellent vibration damping and thermal stability. Two headstocks, each housing one spindle (S1 and S2), are mounted on precise linear profile guideways by Schneeberger to guarantee the highest level of accuracy.

The headstock is moveable in the X and Y directions, driven by integrated motors. Position feedback is provided by linear encoders, ensuring smooth, precise, and repeatable movement.

Spindle System:

Each spindle is supported by precision bearings and equipped with digital rotary encoders from Renishaw. The use of Rexroth-Bosch motor enables precise and smooth movement of all axis.

Automation and Control:

The system is CNC-controlled, with all axes fully motorized. Measurement procedures are performed automatically, minimizing operator influence and ensuring consistent results.

The control system includes:

• A digital control panel

• A permanent license for the measuring software with advanced single-flank analysis features

• An embedded industrial computer

• A complete electrical cabinet and wiring box

Construction and Safety:

The entire system is a stand-alone, enclosed unit with a compact, ergonomic design — suitable for both laboratory and shop-floor environments.

The machine is CE certified and equipped with all necessary safety features to protect operators and ensure compliance with industrial safety standards.

Measurement Performance:

Thanks to its robust design and precision components, the machine achieves outstanding measurement accuracy and repeatability, reaching ≤ 0.001 mm in all parameters.

It is possible to use the machine under both laboratory conditions and on the shop floor if some environment restrictions are kept. The machine does not require any air-conditioned room/laboratory providing that quality grade DIN 5 and lower is measured. For measuring and evaluating of DIN 4 and higher gears, the machine needs to be placed in an air-conditioned (temperature +21 °C ± 1 °C) and dust-free environment.

GEARTEC.CZ External Gear Single Flank Inspection Machine - Motorized

TECHNICAL DATA:

Note: The technical data below are based on the technical design of the machine from a recent installation and may differ for PAI.

Max diameter of measured spur & helical gear: 200 mm

Weight of measured gear, basic machine, max. (standard spindle): 15 kg

Range of mounting distance (X axis): 0 – 250 mm

Range of mounting distance (Y axis): 0 – 180 mm

Measuring speed, max.: 60 rpm

Free rotations in manual mode up to 300 rpm

Rotations for noise and vibration analysis (optional): up to 1500 rpm

Spindle bore pass-through in all length: Ø 30 mm

Total weight approximately: 2000 kg

Fixed shaft angle (standard machine): 0°

Power supply: 400V, 50Hz, 25A

ELECTRONICS & CONTROL SYSTEM:

Control system: Control system of the machine is based on XM21/XM22 embedded controls by Bosch-Rexroth and their D I/O units, incremental and safety modules.

Computer: Industrial computer inbuilt in the wiring box (based on Intel Core i5/i7 processor, 16GB DDR5 RAM, 250GB or above SSD HDD) by Advantech / Bosch-Rexroth running on Microsoft Windows 11 / 64bit Operation system:

Display(s) LCD display

Linear encoders: Heindenhain / Renishaw / Schneeberger digital encoders

Rotary encoders: Heidenhain / Renishaw digital encoders

Servomotor: Indramat (Bosch-Rexroth) system / MAXON motor

Motor units: Bosch – Rexroth / MAXON motor

*Types and brand names of the products above may change.

• The machine’s electronics are built around a fully digital control architecture, ensuring fast data transfer, enhanced safety, and maximum system reliability.

• We have moved away from traditional analogue control and integrated the latest generation of digital technology, delivering the best possible accuracy, integrity, and operational stability.

• All encoders—both linear and rotary—are now digital and utilize TTL signal transmission. Each encoder is factory-calibrated using the manufacturer’s precision calibration tools. In addition, all rotary encoders are fully compensated, achieving an angular precision of ≤ 1 arcsecond.

• Encoder data packets are transferred via high-speed digital lines to the evaluation unit embedded within the machine’s wiring box, ensuring real-time processing and minimal latency.

• All machine movements are managed by a professional PLC system from Rexroth (Bosch Group), while operator and system safety are safeguarded by a dedicated digital safety relay, also from Rexroth.

• This architecture creates a seamlessly integrated and fully compatible system, where every component communicates precisely and efficiently with the others.

• The control panel has also been completely redesigned recently. Traditional analogue joysticks and potentiometers have been replaced with digital counterparts, and all new potentiometers include built-in encoders for precise speed adjustment and control.

• These upgrades significantly enhance the user experience, while preserving the machine’s hallmark compatibility, intuitive operation, and ease of use.

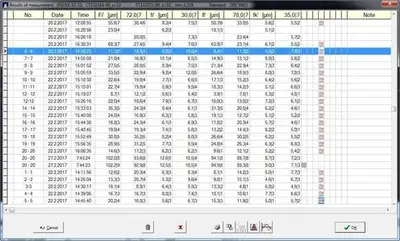

MEASURED DEVIATIONS ACCORDING TO CURRENT STANDARDS:

• Charts show transmission error, speed and acceleration errors.

• The following single-flank deviations are displayed in diagrams.

Single flank deviations:

Fi' - Tangential composite error

fi' - Tooth to tooth error tangential composite error

fl' - Long wave component of the tangential composite error

fk' - Short wave component of the tangential composite error

j - Backlash

Other measurable deviations (optional):

R, E Roundness, eccentricity of bearings surface

Fp - Total pitch error

fpt - Single pitch error

fu - Adjacent pitch error

Fr - Radial runout error

SOFTWARE INCLUDED:

Up-to-date version of the measuring software developed by GEARTEC.CZ is supplied STANDARD with the machine.

• Diagram of speed and acceleration

• FFT analysis module (spectrum and analysis of partial error influences)

• Special mathematic filters for data filtration

• Measuring of several revolutions

• Possibility of segment measurement

• Transparent visualization of results

• Estimation of deviations of each measured gear

OTHER FEATURES:

• User-friendly graphical interface with dialog mode

• No special or advanced PC knowledge required

• Database of gears, measured results and diagrams

• Parameters, measured results as well as measuring diagrams are saved

• Customer´s company logo on all printed reports

• Measured data (reports) is possible to print out, or save as PDF, ASCII or BMP file

• Possibility of saving and numbering of results after each measuring

• Multi-language user interface (English, German, Italian, French and Spanish languages are standard; other languages upon request)

• Measured data can be saved in .CSV file for further processing

• Export of data acc. to Industry 4.0 / OPC-UA protocol (optional)

SOFTWARE AND DATABASE SYSTEM:

• The software package now includes a newly integrated database system, replacing the former database engine based on the Borland platform.

• The new architecture is built on a modern SQL database, a widely used and industry-standard solution that offers greater flexibility, performance, and scalability.

• This upgrade enables seamless integration of the measuring application into local networks, allowing multi-user access and centralized data management.

• Measurement data can be exported in formats compliant with Industry 4.0 requirements, supporting connectivity with factory systems, process control, and quality management platforms.

• With its virtually unlimited capacity and high data integrity, the new SQL-based system ensures future-proof performance and efficient information flow across the organization.

Included accessories:

• GTS200 SF-M fully motorized double flank inspection machine in variation for measuring of external spur & helical gears (as described above)

• Measuring application (in version for spur & helical gears)

• Control unit and all electronics as described above

• Control panel

• LCD monitor, set of keyboard and mouse

• Complete machine documentation in PDF (or other relevant) format. It includes Declaration of Conformity (CE), Machine geometry certification, measuring capability Certification, Wiring diagram, User's manual.

• Complete air-conditioned wiring box with all needed electronics and wires

• Adjustment tools (calibrated control arbors) for regular check of machine geometry

• Basic protective elements

INCOTERMS 2020: Ex WORKS - Duty, VAT, other taxes are not calculated herein.

We use cookies to improve your experience. Privacy Policy.